Stainless Steel Sintered Wire Mesh Filter

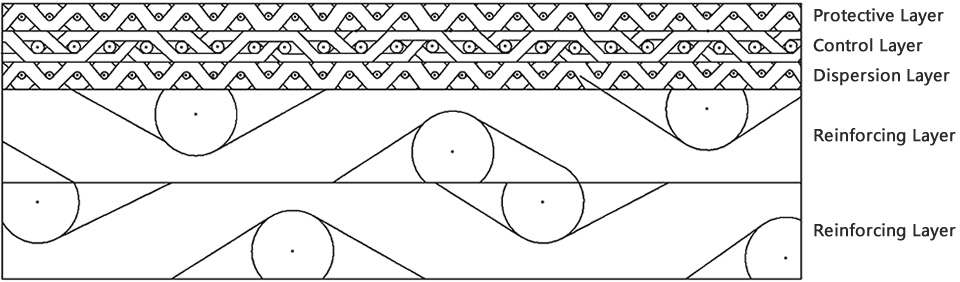

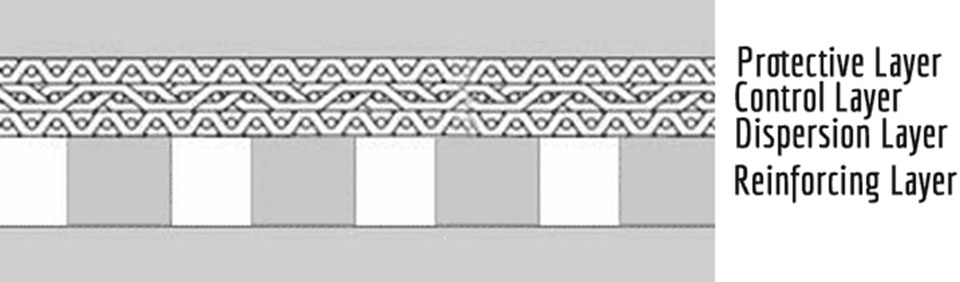

Sintered wire mesh filter is a type of porous filter media that is produced by sintering multiple layers of woven wire mesh. Sintering is a manufacturing process that involves bonding the mesh layers together by applying heat and pressure, without using any additional adhesives or binders. This process creates a sturdy and durable material with uniform pore sizes and excellent filtration properties.

What is the main material of sintered wire mesh?

The main material used for sintered mesh is typically stainless steel, e.g. 316L, 316, 304, 304L. Stainless steel is chosen for its excellent mechanical properties, corrosion resistance, and high temperature resistance, making it suitable for a wide range of industrial applications. Other materials such as bronze, nickel alloys, and titanium can also be used depending on specific requirements. However, stainless steel is the most commonly used material for sintered mesh due to its durability, chemical stability, and availability in different grades to suit various operating conditions.